Eco Corrugated Pack - Embrace Change, Embrace Green!

Mission:

We are dedicated to providing eco-smart eco-friendly printing and packaging machinery solutions, with the goal of becoming a pioneer in sustainable development. We firmly believe that taking care of the environment is the duty of every business, and through our efforts, we will work together to protect our magnificent Earth.

Eco Corrugated Pack provides custom printing and packaging machine solutions to high-quality corrugated carton box factories and offset printing carton manufacturers in the Middle East.

Eco Corrugated Pack assist you in building an eco-smart and eco-friendly factory.

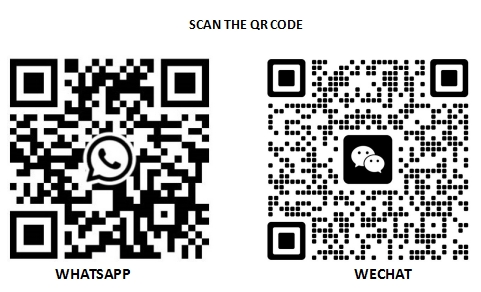

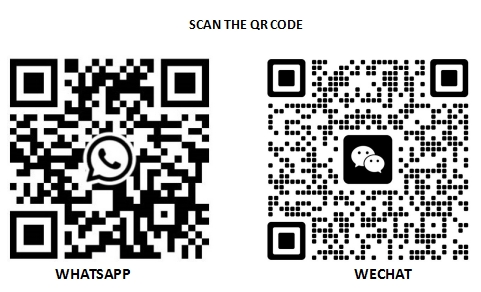

ecocorrugated@gmail.com

2 Ply Corrugated Cardboard Production Line,1800mm,150m/min, 320C

|

Model |

Equipment Name |

UNIT

|

QTY |

|

ZJ-V5B |

Hydraulic shaftless mill roll stand |

a |

2 |

|

|

Paper trolley |

a |

4 |

|

RG-1-900 |

Preheater |

a |

2 |

|

SF-320C |

Fingerless type single facer |

a |

1 |

|

ZDF |

Conveyor bridge |

set |

1 |

|

DHE-150 |

Single corrugated Cutter (Spiral knife Crosscutting, NC thin knife slitting, down stacking) |

a |

1 |

ZJ-V5B Hydraulic Shaftless Mill Roll Stand

※Structural feature:

★Adopt hydraulic drive to complete the paper clamping, loosen, remove for the medium, translation left and right and others,the lifting of the paper adopts hydraulic drive.

★Brake adjustable adopts multipoint braking system.

★Every stand matched two sets paper car , and they can paper on the both sides at the same time.

※Technical parameters:

1、The range of clamping paper:MAX1800mm

2、Clamping diameters:MAX¢1500mm MIN¢350mm

3、 Main shaft diameter of paper holder:¢242mm

4、Gas source work pressure(Mpa):0.4---0.8Mpa

5、Equipment size:Lmx4.3*Wmx1.8*Hmx1.6

6、Single weight:MAX4000Kg

※Hydraulic system parameters:

1.Work pressure(Mpa):16---18Mpa

2.Lifting hydraulic cylinder:¢100×440mm

3.Clamping hydraulic cylinder:¢63×1300m

4.Hydraulic station motor power:3KW --380V -- 50Hz

5.Solenoid valve voltage:220V 50 Hz

Paper Trolley

※Structural feature:

★The whole track buried, the main frame of the 14th Channel steel with ¢ 20mm cold drawn welded round, length of track 4510mm.

★Each paper holder matched two sets paper trolley, and paper on both sides at the same time.pull the roller paper to the right place.

RG-1-900 Preheater

※Structural features:

★Preheat roller accord the pressure container national standards,and enclose the pressure container certificates and inspection certificate.

★Each roller surface after grinding precision grinding and dealing with hard chrome plating, Surface friction is small, durable.

★Electromotion adjustment angle, and angle can rotation adjustment the preheat area in the range of 360°.

※Technical parameters:

1、Effective width:1800mm

2、Diameter of preheat roller:¢900mm

3、Angle adjustment range:360°rotation

4、Angle shaft diameter:¢110mm×2

5、Steam temperature:150-180℃

6、Steam pressure:0.8-1.3Mpa

7、Equipment size:Lmx3.3*Wmx1.1*Hmx1.3

8、Single weight:MAX1800Kg

9、Working power:380V 50Hz

10、Motor power:250W short(S2)working system

SF-320C Singerless Single Facer

※Technical parameters:

1、Effective width:1800mm

2、Operate direction:left or right(Determined in accordance with the customer's facility)

3、Design speed:150m/min

4、Range of temperature:160—180℃

5、Air source:0.4—0.9Mpa

6、Steam pressure:0.8—1.3Mpa

7、Equipment:Lmx3.5*Wmx1.7*Hmx2.2

※Roller diameter parameters:

1、Corrugated roller:up¢313mm down¢316mm pressure roller:¢320mm

2 、Glue roller:¢240mm fixed paste roller: ¢140mm preheat roller:¢402mm

※Powered motor parameters:

1、Main frequency drive motor:18.5KW rated voltage:380V 50Hz Continuous (S1) working standard

2、Suction motor:11KW rated voltage:380V 50Hz Continuous (S1) working standard

3、Glue reducer:100W rated voltage:380V 50Hz Continuous (S2) working standard

4、Glue gap motor:250W rated voltage:380V 50Hz short(S2) working standard

5、Glue pump motor:2.2KW rated voltage:380V 50Hz Continuous (S1)working standard

※Auxiliary equipment:

1、Special pulley crane configuration tile roll maintenance, convenient to use when maintenance tile roll, and fast.

2、Configuring an external guide pulley crane to lengthen the trip, in order to successfully remove the line outside the repair parts.

ZDF Conveyor Bridge

※Structural feature:

★This part of the main frame with channel, beam, angle and so connected together.

★Other sides are equipped with safety barriers and security herringbone pedal operation face a safety ladder, ensure staff safety and ease of operation.

★Independent variable frequency motor lifting mechanism, PVC conveyor belt, a single watt of cardboard into a wavy rule stable.

★All roller surface after grinding hard chrome plated.

★Bridge over the auxiliary high-strength composite sheet, smooth, durable, low friction, reducing transportation resistance cardboard.

※Technical parameters:

1、Working width:1800mm Highest height:3000mm Working speed:150m/min

2、Paper roll and tension roller: ¢130mm Conveyor roller:¢180mm

3、Single-sided corrugated lift motor:3KW (frequency) 380V 50Hz Continuous(S1)Working standard

DHE-150 Single Corrugated Cutter(Spiral Knife Crosscutting,NC Thin Knife Slitting,Down Stacking )

※Structural features:

1、Store 200 groups of orders, the man-machine interface, the screen displays information can be found at any time, modify, append, cancel.

2、American Emerson servo motor drive controller, high-performance synchronous servo motor drive.

3、Cutting Machine adopts inlaid front steel blade structure, hardened gear grinding backlash-free transmission, high precision and long life.

4、Host wall of gray cast iron, rigidity, vibration resistance.

5、Stacking adopt gantry platform lifting, Reach a certain number of right-angle transverse, three sections of the paper, some hair design paper roll straight bend output second overlapping fixed-length buffer,three part points Pneumatic separate. The maximum length of stacked is 1.6 meters .This machine is suitable for efficient production color printing business.

6、Full servo motor control, change order fast, for a single time 1-3 seconds.

7、Using thin tungsten alloy steel knife,blade sharp,the using life is more than 8000000 meters.

8、Brothers for computer-controlled, automatic or manual knife sharpener can be divided trimming knife edge, increase productivity.

9、Imported synchronous drive system, precision accurate, long life, low operating noise.

10、From high-quality imported industrial computers and high-performance programmable controller configuration, lower computer control system.

※ Technical parameters:

1、The maximum working width:1800mm

2、operation direction:left or right(Determined in accordance with customer plant)

3、The maximum mechanical speed:150m/min

4、Mechanical configuration:Computer spiral knife crosscutting

5、Cutting length:300-1600mm

6、Minimum slitting width:180mm

7、Precision Cutter:±1mm(Uniform) ±1.5mm(Non-uniform)

8、5 groups ¢200blades

※Roller diameter parameters:

1、Cross on the knife shaft diameter:¢200mm Balancing done deal

2、Cross under the knife shaft diameter:¢200mm Balancing done deal

3、Under the pull roller diameter:¢156mm Balancing done deal

Note: After all have been grinding rollers, hard chrome plated at (upper and lower arbor exception) processing.

※Power motors and electrical parameters:

1、Main drive motor power:12.5KW Full AC synchronous servo motors

2、Pull the paper motor power:3KW(Frequency Control)

3、Feed motor power:1.5KW(Frequency Control)

4、Transverse motor power:0.75KW(Frequency Control)