Eco Corrugated Pack - Embrace Change, Embrace Green!

Mission:

We are dedicated to providing eco-smart eco-friendly printing and packaging machinery solutions, with the goal of becoming a pioneer in sustainable development. We firmly believe that taking care of the environment is the duty of every business, and through our efforts, we will work together to protect our magnificent Earth.

Eco Corrugated Pack provides custom printing and packaging machine solutions to high-quality corrugated carton box factories and offset printing carton manufacturers in the Middle East.

Eco Corrugated Pack assist you in building an eco-smart and eco-friendly factory.

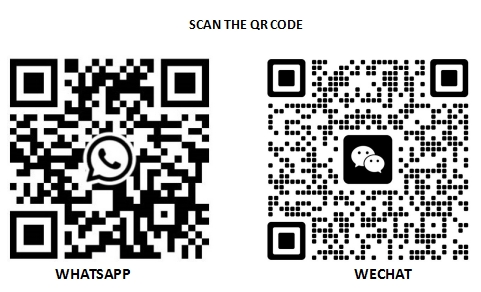

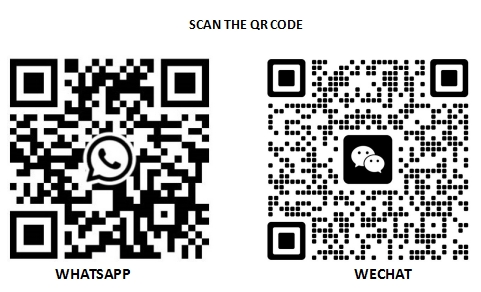

ecocorrugated@gmail.com

High-Definition Flexo Printing Slotting Diecutting Machine

Lead Edge Feeder Unit

Lead-edge Feeding System

Lead-edge suction feeding system, easy operation, high accuracy,(adopts lead feeder system).

7.5KW high pressure centrifugal fans, according to the cardboard warping degree of frequency control pressure.

Left and right side baffle position electrically adjustable, screw-driven.and can remember by computer.

Feeding Roller: Double Feeding Roller

Lower feeding roller adopts embossed rollers, hard chrome-plated, wear and smooth.

According to cardboard thickness, adopt worm gear box gap tuning, with locking device. Adjustment range 0-12mm

Vacuum Transfer Printer Unit

Printing Roller

Electric 360° adjust printing roller, automatic digital display adjustment,remember store digital.

Installed with foot switch to control plate roller reversing, convenient change plate.

Auto-zero function,order memory.

Pressing Roller

Adopt high quality seamless delicately processing, dynamic balance adjustment, stable operation.

Gear adopt backlash adjustment mechanism, adjustment none-affect gear enunciation, guarantee transmission accuracy.

Printing roller can be adjusted for a distance 0-12mm.

Anilox Roller/CERAMIC ROLLER

Steel anilox roller mesh: 150-300 line

Ceramic roller mesh: 300-750 line

Rubber Roller

Rubber roller drum type middle part higher, to ensure ink quality.

Rapid spaced spinner self-locking device, ensures uniform ink.

Ink distributing roller independent drive mechanism, ensure ink quality.

Fully Computer Slotter Unit

Computer auto control cardboard size by Linear guideway.

6/8 shaft with pre-creasing line, creasing line, slotter line.

Slotting phase and box height, computer and electric digital control.

Preload, creasing gap adjustment adopt computer and electric digital control.

The slotter knife stock gap adjustment adopt self-locking structure.

Die Cutting Unit With Servo Motor Drive

Horizontal phase, computer and electric digital control, range ±5mm.

Rubber roller and die roller gap use computer and electric digital control.

Adjust the transfer roller use computer and electric digital control.